AUTOMATIC ASSEMBLY MACHINE

click for dedicated page

Apiel Automation produces machines and automated lines to make even complex assemblies.

The assembly can be made for screwing, gluing or fitting.

We can provide from simple pick and place systems to complex multi-axis automatic machine

for the assembly of several tens of elements Our systems can be a single machine or automatic assembly line.

To store the individual components of the assemby, are used: pallet chuck,

accumulation tables, vertical feeders, baskets.

If the component allows, we also use vibrating feeders.

The machines we produce, include cartesian robot for handling of components

and the warehouses for the ordered storage the components.

Due to the specificity and complexity of applications, the machines are adapted to the needs of each customer.

We have developed systems for the assembly of fittings, guide the furniture industry

and for the production of displays and samples ceramic tiles.

AUTOMATIC PROFILE

BAR FEEDERS

click for dedicated page

Apiel Automation manufactures bar feeders with non-circular or complex-shaped sections

such as profiles for ventilation systems and window frames.

The feeders consist of a bar magazine and a bar pusher.

The bar warehouse can be either vertical or horizontal.

The bar pusher can be pneumatic, hydraulic or electrically controlled.

The electric bar pusher uses a PLC-controlled servomotor to perform the feeds defined in the PLC.

The horizontal bar warehouse can hold several hundred meters of profile.

AUTOMATIC LOADING/UNLOADING

OF MACHINE TOOLS

click for dedicated page

Apiel Automation designs and manufactures devices for loading, unloading and handling of finished

and semi-finished products produced by chip removal or molding.

The movement of the pieces takes place by means of Cartesian manipulators produced by us

or by means of commercial articulated arm robots.

In simpler applications we make gravity loaders.

The picking of the parts to be loaded can be carried out from bulk crates

with subsequent mechanical orientation or with a vision system.

Both the loading and unloading operations can be carried out using special containment baskets.

LID DISPENSER

click for dedicated page

This product is used in filling lines for buckets with snap-on lids.

The machine places a lid over the bucket, after filling.

The lid is snapped onto the bucket in a pressing station.

Our applicators are fully pneumatic.

The loading of the lids can be done while the machine is running.

The main adjustments are equipped with a position indicator to facilitate format change.

AUTOMATIC MEASURING MACHINE

click for dedicated page

Our measuring machines are characterized by the automation of the measuring process.

Measuring machines are aimed at those who produce parts that require dimensional verification

on high percentages of production.

In order to reduce the use of manpower dedicated to dimensional control,

we create machines that take the part to be measured and position it in one or more measuring stations.

After taking the measurements, the part can be directed to two or more exits,

depending on whether it is within the tolerance range or not.

It is possible to print a report for non-compliant parts and it is also possible to define statistical reports.

The machines are designed and built for the specific measurement need.

INDUSTRIAL MANIPULATORS

WITH BRIDGE CRANES

click for dedicated page

This overhead crane is used in production and assembly departments where there is a need to move

light and bulky components over fairly large areas.

For movement in the direction of the two ground running tracks, a pair of motors are used,

while transverse movement is manual.

The load is lifted by means of a manipulator or electric winch.

The controls are centralized on a push-button panel with buttons and joystick.

Lifting commands can also be given by means of a handle sensitive to the vertical force

applied by the operator: the greater the force applied, the greater the translation speed.

AUTOMATIC METAL

WASHING MACHINES

click for dedicated page

The washing machines we produce are designed to meet the needs of washing parts

during the processing phases where the orderly flow of components must not be altered.

Washing is done by means of high-pressure water: a series of nozzles are moved by one or

more manipulators along trajectories that allow the required cleaning to be obtained.

Another application is the group washing of products attached to support frames:

in this case too, the washing nozzles are directed to the points where cleaning must be carried out.

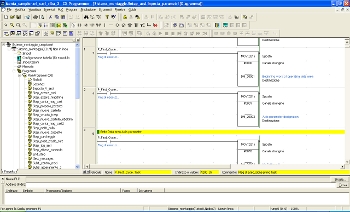

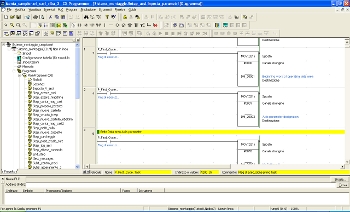

ENGINEERING, DESIGN ON

ACCOUNT OF THIRD PARTIES

click for dedicated page

Mechanical design and development of PLC and HMI programs for Omron Lenze Siemens Wintek and ESA products.

In addition to design, we can manufacture the product and carry out testing in our workshop.

CARD PERSONALIZATION

click for dedicated page

Apiel creates devices for the recovery of scratch off film, used in the personalization of telephone cards.

The device is applied in the hot foil printing groups that apply the film that obscures the secret codes.

The recovery device allows to halve the use of scratch off: the reels of used film,

rewound during the printing process of the virgin film, are mounted on the recovery device

for a second print.

The recovery device is an aligner able to keep the used scratch correctly positioned

under the hot foil wheel during the printing process.

The rewinding device rewinds the used reels of scratch off to be reused in the recovery devices.

Rewinding the scratch is necessary when you have to reuse scratches with asymmetric graphics:

without rewinding, recovery of the scratch leads to having overturned imprints.

REMOTE CONTROL FOR

MACHINES AND PLANTS

click for dedicated page

The remote control systems we produce allow us to detect the status of machines used for production.

Questi apparati sono particolarmente utili per aziende con diverse unitÓ produttive;

in particolar modo per stabilimenti delocalizzati in nazioni estere.

Our monitoring devices can be applied to both recently produced machines and older machines.

We do not need to enter the software of the machines to be controlled:

we install a PLC on the machine that detects, both with the sensors already present.

SPECIAL MACHINES

click for dedicated page

To meet specific production needs, we design and manufacture machines according to the customer's specifications.

We specialize in the design and manufacture of automatic machines with limited weight and dimensions.