PLASTIC BUCKET

LID APPLICATOR

The plastic lid applicator produced by Apiel Automation is a device that places the lid on buckets or drums after they have been filled. The lid applicator places the lid over the plastic bucket or drum, without closing it. The container is closed in a subsequent station where a press crushes the lid onto the bucket until it fits together.

The applicator can work with both round and oval lids. The buckets must be perfectly centered under the applicator to align the edge of the lid with the edge of the bucket. The conveyor that moves the buckets must have a centering device to align the axis of the bucket with the axis of the applicator. The centering device can be supplied with the applicator. The application axis of the lid is fixed as the size of the lid varies.

The standard model of lid applicator can handle the following sizes of plastic lids and buckets:

- circular with diameter from 160 to 400mm

- ovals from 200x160 to 450x400mm

- Bucket height from 150 to 450mm

The lid magazine has a capacity of 800mm equal to approximately 160 lids. The applicator is able to apply over 20 lids per minute. The autonomy at the application speed of 20 lids per minute is approximately 8 minutes.

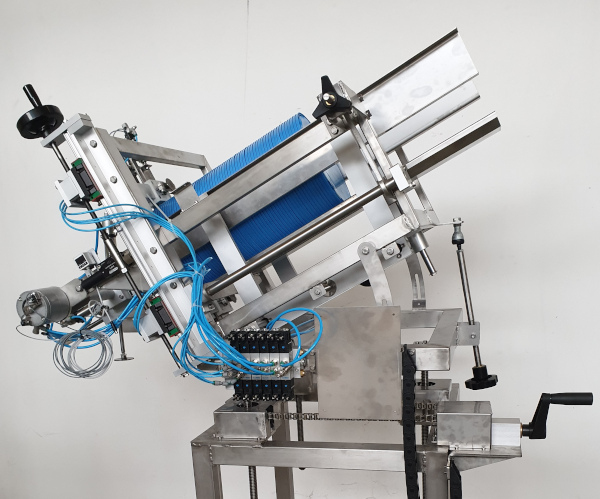

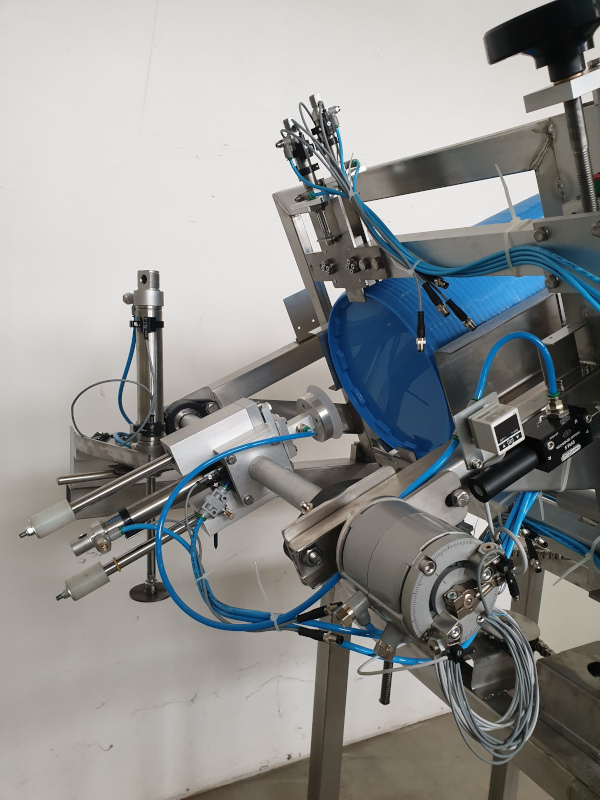

The lid applicator (or lid dispenser) is made entirely of AISI304 stainless steel and 6060 aluminum alloy (anticorodal). The aluminum parts are anodized. The bolts are A2 stainless steel. The lid applicator does not have electric actuators: the two movements of gripping-positioning and rotation of the lid are pneumatic. The pneumatic actuators are Festo with magnetic sensors.

The lid applicator / lid dispenser can be supplied with or without an electrical system. In the basic version without an electrical system, only the sensors for the magnetic cylinders and the digital vaquo switch will be supplied. The 'lid warehouse almost empty' and 'lid warehouse empty' photocells are not part of the supply but must be ordered separately. The version with an electrical system will have an Omron CP1 PLC with a 4.3" Weintek operator panel. The electrical system will use 3 inputs and 3 outputs to communicate with the production system.

Technical description

The lid applicator consists of a base and a lid magazine.

The base is made of AISI304 tubes and rests on the ground with 4 adjustable feet.

3 trapezoidal screws are applied to the base which, by means of 3 nuts, support the lid magazine.

The nuts are controlled by a chain that meshes with a pinion; the latter is rotated by a pair of bevel gears and a crank.

A position indicator is mounted on the crank shaft which indicates the distance between the suction cup

and the bucket conveyor surface.

By turning the crank, the lid magazine rises and lowers.

The lid magazine consists of a support frame that rests on the 3 trapezoidal screws whose movement allows the vertical position of the lid to be varied. The lid holder frame that supports the stack of lids is hinged to the support frame. The lid holder frame is inclined at an angle sufficient to slide the stack of lids towards the suction cup. The angle can be varied with a screw: this adjustment must be extraordinary because it also involves moving the application axis of the lid, altering the vertical position of the suction cup shown by the specific indicator and also the need to adjust the mechanical limit switches of the rotating actuator that rotates the suction cup. The lid holder frame has 3 guides that support the stack of lids: two lateral guides and a vertical guide. The lateral guides are adjustable by means of a right-left screw that keeps the median axis in line with the suction cup. The lateral guides distance adjustment shaft has a position indicator to facilitate format change. The vertical guide is adjustable in height by means of a screw with position indicator. At the lower end of the guides that support the stack of lids we have two pairs of stops. The pair of stops allows the first lid of the stack to be isolated from the remaining ones. The suction cup can rotate in the vertical plane from the vertical position to the position aligned with the stack of lids. The suction cup translates radially by means of a pneumatic cylinder. The lid is gripped by rotating the suction cup in line with the stack of lids and moving it until it touches the first lid. By applying vacuum, the first lid is hooked and released from the stack by taking the external stops. The suction cup extracts the lid and rotates it vertically and then lowers it onto the bucket. With the lid resting on the bucket, the locking cylinder is lowered and the suction cup is raised. By opening and closing the latches, the stack of trays cover a lid.

Download the PDF catalog of the lid applicator - lid dispenser

![]()