Apiel Automation builds 3 different bar feeders that differ in storage capacity and the type of work carried out on the rods.

The main features are:

- HIGH CAPACITY BAR FEEDER

- Automatic feeder for presses and cutting machines used for cutting rods

- Designed to work with aluminium extrusions even with complex sections

- Machine with automatic bar pusher device

- Possibility to create machines with conveyor for moving the whole bar

- Loading of the bars during operation of the machine

- VERICAL FEEDER

- Economic automatic feeder, to store a limited number of rods.

- It can also work with steel bars with a section of up to 80x20

- Feeder with automatic bar feeding device, for cutting or with conveyor for the transfer of the whole bar

- FEEDER FOR 3D LASER CUTTING SYSTEMS

- Dual operating modes: supply for cut or feeding for rod work.

- Ability to work bars of different lengths (from 300mm to 3000mm)

- Ability to load the rod during processing.

- The rods are supported in the work area to prevent deflection.

- The feeder can work with thin section bars

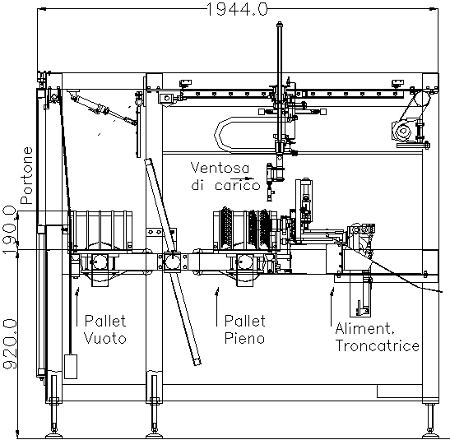

AUTOMATIC PROFILED BAR FEEDERS ALIPRO6000

The bar feeder for profiles, ALIPRO6000, is used with cut-off saws or presses,

to cut strongly asymmetric profiles (typically extruded aluminum).

These profiles are used in windows and vents for air conditioning production.

The feeder is built in three distinct versions, with and without a pallet changer and fins.

The profiles that can be processed can be divided into two types:

stackable profiles and not stackable profiles.

Stackable profiles are those that create straight stacks,

these profiles are stored in magazines specifically designed for the profile.

In these cases we can achieve a total capacity up to 800 meters.

The right photo represents the profiles can be stacked.

The not stackable profiles (right photo, profile on the left) are inserted in special supports,

without reaching high storage capacity.

The fins profile (right photo, profile on the right) are stacked alternately.

In order to be processed, fin profiles need the use of a particular model of rods loader.

The photos on the right and below on the right represent the interior of the automatic loader and the section of the same.

The automatic loader shown has a pallet changer.

The grip of the rod is made with the suction cups.

The profiled rod is carried on a feed system that feeds the machine tool used for cutting.

The suction cups hooking rods are moved by a set of three cartesian axes

with induction motors and inverter, with encoder feedback.

The hooked profile is placed on the feeding line.

The bar pushing is obtained by means of a pair of grippers: a mobile one and a fixed one.

The movable gripper is driven by a brushless servo motor.

The transmission is made with a recirculating ball screw.

The moveable gripper runs on guide with recirculating balls carriages.

The cutting precision is 5 / 100 mm.

On the control panel you can define the length of each piece in which the rod is to be divided.

This allows maximum reduction of wastage.

The length of cut has neither a minimum nor a maximum length.

The automatic loader is controlled by an Omron PLC. The operator interface uses a panel 5.7".

Download the pdf catalog of high-capacity charger

AUTOMATIC VERICAL FEEDER CariVert6000

The vertical bar feeder is produced in 2 different models: for rods up to 6 meters CariVert600 and rods up to 4 meters Carivert4000.

The automatic rods loader is an economical solution and efficient way to automate the feeding of machines tools for cutting or machining.

The bars stored into the large bars warehouse, allow the feeded machine tools, to work without staff .

The load of the rods into the warehouse can be made at any time (even when the feeder is working).

The automatic loader is constituted by the vertical bars warehouse, the loading and unloading device and the bar pusher for the feed of the bar being machined.

The warehouse has a capacity of 27 bars and is suitable for full section bars or sections with various profiles.

The loading / unloading group has a plane for supporting the bundle of rods.

The operator will extract the single rod from the bundle and will rest it on the bar load supports.

The single rod will be loaded automatically in the rods warehouse.

The loading operation can also occur during the feed of the bar for cutting.

When insertion of the bar is completed, the bar is raised by the supports attached to the chains of the bars warehouse.

The storage capacity is saturated when all supports are filled with rods.

The output of the bars is done by lowering the rod supports up to release the bar on the outlet supports.

The bar is moved on motorized roller; starting the movement of the roller, the rod is ejected toward the rod pusher.

The feed of the bar inside the cutting machine is realized with a bar pusher, consisting of a fixed gripper and one mobile.

There are 2 versions of bar pusher: pneumatic or servo.

The pneumatic bar pusher is the most economical solution and usable when the cutting machine has a stopper

for stopping the feed of the bar in the cutting position.

When there isn't a stop for the bar or when the feed of the bar is variable within the bar, is used the servo bar pusher.

The movable gripper, driven by a servomotor, realizes advances set on the operator panel of the machine.

At the exit of feeder you can have a motorized roller to reach the machine used for processing.

The output roller conveyor of can be equipped with an accessory which allows the bar to be rotated during processing.

Download the pdf catalog of vertical feeder

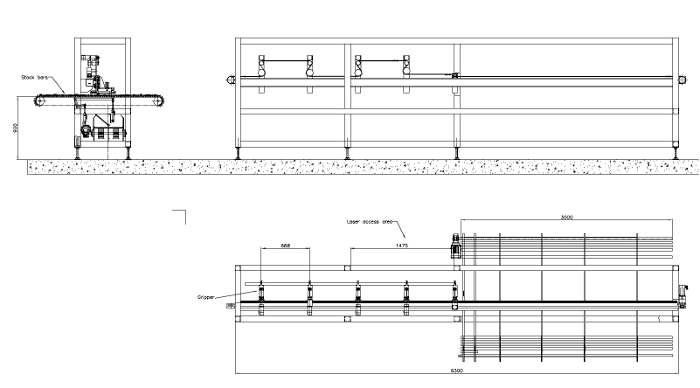

FEEDER FOR 3D LASER CUTTING SYSTEMS

This feeder is designed to work bars of different sections, with a 3D laser.

The 3D laser is a laser fiber optic with the cutting head installed on the wrist of a anthropomorphic robot.

The feeder allows you to place the bar to work in the operational area of the laser.

The feeder has two operating modes:

- machining and cutting of the bar

- machining of the bar in its original length.

In the first working mode, the bar is fed in the working space of the laser; completed processing,

the piece is cut from the rest of the bar.

In the second mode, the bar has the length of the finished piece; completed processing,

the bar is repositioned on the finished parts warehouse.

The essential components of the machine are:

-

Steel tubular 80x80 frame that supports the parts of the feeder and safety protections.

An opening on the side of the frame allow the use of the robot that carries the laser.

-

Bars Warehouse: stores both the rods to work that worked.

The warehouse consists of 6 chains, with profiled holders for the support of the bars.

The position of the chain is adjustable to facilitate the support of the rods.

-

Bars elevator: removed worked bar from the grippers, and places it on the chain.

The chain takes a step forward and elevator raises the bar not worked and inserts it in the grippers.

The removal of the bar is only needed when the same should not be divided into chunks.

-

Group bar feeder: consisting of a tubular 100x100 supporting a plate with a pair of recirculating ball-bearing linear guides.

On the guides run the 5 carriages carrying the grippers.

At one end of the tube is installed a servomotor with low backlash planetary gearbox

which controls the longitudinal movement of the grippers by means of a toothed belt.

-

5 grippers that hold and lock the bar.

The first gripper (the one closest to the motor) is connected permanently to the belt and is constantly engaged on the bar;

This gripper (which we call master) controls the longitudinal motion of the bar and is equipped

with a linear encoder to ensure high accuracy positioning.

The other 4 grippers move together to master gripper, in the forward movements of the bar.

The same grippers are equipped with motors to vary the position taken on the bar, so as to ensure maximum support in the work area,

allowing processing at each point of the bar, to facilitate the cutting of segments of an entire rod.

Each gripper has: a vertical jaw to lock bar, an horizontal jaw which keeps the bar in a horizontal position against a reference.

-

Waste conveyor, positioned below the bar in the working space,

collects and transports the cut material in a container outside.

-

Conveyor finished pieces, placed under the bar in the working space,

collect the cutted pieces and takes them to an outer container.

A deflector directs cut material on a conveyor or the other depending on the commands received from the laser system.

-

Electrical panel with PLC Omron and color touch screen operator panel.

Download the pdf catalog of feeder for 3d laser cutting systems